New Ford Truck Body Design Saves Hours in Repair Time

A company known for listening to its customers also listens to those who fix their trucks.

One thing most of we Ford truck fans rarely think about is repairs. Namely, the way certain design elements relate to repair difficulty. But when you run a body shop, these are the things that have a huge impact on your business. After all, difficult repairs require training, experience, and lots of time. And time is precious when you’re trying to get something fixed and out the door.

One particularly difficult repair on pre-aluminum Ford truck models is the front apron tube. Repairing an old damaged front apron tube is something that Body Shop Business calls “a daunting proposition.” And even Ford senior damageability engineer Gerry Bonanni admits that it’s a “beast of a repair” in the automaker’s latest On Target newsletter.

What makes the front apron tube such a painful fix on previous F-150 and Super Duty models? Well, it all boils down to accessibility. Repair shops have to tear down the A-pillar and remove the instrument panel just to gain access to it. Ford received a ton of feedback on the issue, and obviously took it to heart when designing their new trucks.

‘This new design not only makes the overall apron-tube repair easier, it now saves an incredible amount of time, up to eight hours.’

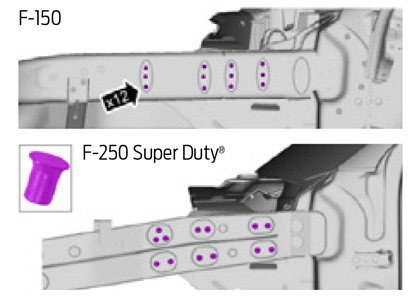

“The apron tube on both vehicles has been pulled further out from its original location inside the vehicle and is now much easier to access,” Bonanni notes. “Repairers no longer have to remove the A-pillar or even touch the instrument panel. This new, modular design not only makes the overall apron-tube repair easier and more straightforward, it now saves an incredible amount of time, up to seven or eight hours.”

Additionally, a special powder coating on steel rivets, fasteners, and adhesives prevents them from interacting with the aluminum panels. The powder also appears on all genuine Ford replacement parts, which helps guarantee a more robust repair.

Ford has always demonstrated a willingness to listen to its customers and make changes to suit them. And that doesn’t just mean making them better to own – it also means making them easier to repair.