Is my pinion seal shot?

#16

Man gearman you make it sound so scary I never want to do any rear axle work again. But you are correct has I stated above it takes above average mechanical skills. You care to back me up on the crush sleave replacement? Dnale, if you have any doubts let the pros repair it, just make sure they don't just slap a seal in it unless you like russian roulette.

#17

Nicely done, gearmanx17.

As a region service manager for our Axle/Brake division some several jobs ago, I rarely found anyone who could put that job on paper as well as you did. I'll bet you don't have any 'returns' (un-happy customers) on your jobs, either.

It's also a good idea to check the pattern (toe/heel) for correctness as well as checking backlash -- and I'm sure that you can also write about that -- and I also know that if you got into that narrative, your post would be a small manual .

.

If anyone else is interested in some oranges to tangerines comparison training (we don't make things small enough for pickup trucks), see the on-line manuals at: http://truck.eaton.com/na/literature...ts/axle_sm.htm

As a region service manager for our Axle/Brake division some several jobs ago, I rarely found anyone who could put that job on paper as well as you did. I'll bet you don't have any 'returns' (un-happy customers) on your jobs, either.

It's also a good idea to check the pattern (toe/heel) for correctness as well as checking backlash -- and I'm sure that you can also write about that -- and I also know that if you got into that narrative, your post would be a small manual

.

.If anyone else is interested in some oranges to tangerines comparison training (we don't make things small enough for pickup trucks), see the on-line manuals at: http://truck.eaton.com/na/literature...ts/axle_sm.htm

#18

Thanks Jim,

On a weekly basis I communicate with people at Eaton Axle & transmission divisions in Kalamazoo, MI, Henderson, Ky and other points around the U.S.A.

Many times a month I meet and have the opportunity to help people that are trying to repair their own manual transmission, transfer case or differential themselves. Manual transmissions (as you already know) are more consise in determing if it is correctly reassembled. In general, more care is needed for differential repair or rebuild. I don't like seeing people waste money, and having to have the repair done a second time by a professional.

I do have a very large & happy customer base at my vocation!

Thanks, gearman

On a weekly basis I communicate with people at Eaton Axle & transmission divisions in Kalamazoo, MI, Henderson, Ky and other points around the U.S.A.

Many times a month I meet and have the opportunity to help people that are trying to repair their own manual transmission, transfer case or differential themselves. Manual transmissions (as you already know) are more consise in determing if it is correctly reassembled. In general, more care is needed for differential repair or rebuild. I don't like seeing people waste money, and having to have the repair done a second time by a professional.

I do have a very large & happy customer base at my vocation!

Thanks, gearman

#20

Jim, Do You work for transmission, axle, or clutch division? I work many times with people in midrange transmission (Bob D. Brown) and various contacts in Henderson, Ky, axle div.. Occasionally, I work with personell at TCM-HELP line.

TCM-HELP has a Rep. in the Southern CA region that is the best. I wish I could remember his name--he has helped me many times through TCM help line. Thanks, Charlie

TCM-HELP has a Rep. in the Southern CA region that is the best. I wish I could remember his name--he has helped me many times through TCM help line. Thanks, Charlie

#21

Wellllllllllllllll

Technically, I now work in the Aftermarket Division. I started out with the Brake Division in 1973, it was consolidated with the Axle Division in 1982 -- which was consolidated with the Transmission Division a few years later -- which includes the Roadranger Field force -- where your TCM (Roadranger) rep works. I'm at WHQ, where Engineering/Marketing/Service for all except Clutch is located (they're in Auburn IN).

BTW, We sold the Axle/Brake division (J.O. Eaton started the Eaton Axle Co 100 years ago -- it was the original company which became the corporation/name) to Spicer/Dana a few years ago -- and we bought the Clutch business from them. We continue to be their marketing representatives (that's why you see the Spicer/Dana/Eaton names on the Roadranger web) -- and Dana built a beautiful HQ down the highway from us -- and we stay closely partnered.

Technically, I now work in the Aftermarket Division. I started out with the Brake Division in 1973, it was consolidated with the Axle Division in 1982 -- which was consolidated with the Transmission Division a few years later -- which includes the Roadranger Field force -- where your TCM (Roadranger) rep works. I'm at WHQ, where Engineering/Marketing/Service for all except Clutch is located (they're in Auburn IN).

BTW, We sold the Axle/Brake division (J.O. Eaton started the Eaton Axle Co 100 years ago -- it was the original company which became the corporation/name) to Spicer/Dana a few years ago -- and we bought the Clutch business from them. We continue to be their marketing representatives (that's why you see the Spicer/Dana/Eaton names on the Roadranger web) -- and Dana built a beautiful HQ down the highway from us -- and we stay closely partnered.

#22

Originally Posted by gearmanx17

Once backlash is set, and caps are torqued the final time, remove pinion nut and yoke. Install the new seal. Again, tighten the "New" pinion nut down, being Very, Very, careful not to overtighten the pinion bearing, or future failure will occur.

How tight do you tighten the new nut? Is there a specific torque or preload? Doesn't removing the old nut and replacing it with a new one screw up the whole bearing preload process? If not, why go through the whole process of taking the diff apart when replacing the seal? Sounds like your procedure leaves tightening the new nut guesswork?

I'm about to replace my pinion seal soon and I want to make sure I get it right.

#23

Originally Posted by bachflomid

How tight do you tighten the new nut? Is there a specific torque or preload? Doesn't removing the old nut and replacing it with a new one screw up the whole bearing preload process? If not, why go through the whole process of taking the diff apart when replacing the seal? Sounds like your procedure leaves tightening the new nut guesswork?

I'm about to replace my pinion seal soon and I want to make sure I get it right.

I'm about to replace my pinion seal soon and I want to make sure I get it right.

I do not use the "scale method"; just do it by feel, since I have rebuilt probably three thousand differentials in my career.

If you get the pinion preload too tight, the bearings will spall and you will contaminate every bearing in the axle assembly.

#24

Originally Posted by bachflomid

How tight do you tighten the new nut? Is there a specific torque or preload? Doesn't removing the old nut and replacing it with a new one screw up the whole bearing preload process? If not, why go through the whole process of taking the diff apart when replacing the seal? Sounds like your procedure leaves tightening the new nut guesswork?

I'm about to replace my pinion seal soon and I want to make sure I get it right.

I'm about to replace my pinion seal soon and I want to make sure I get it right.

Here how you do it on jack stands. What ever you do, do not use air tools on a rear end.

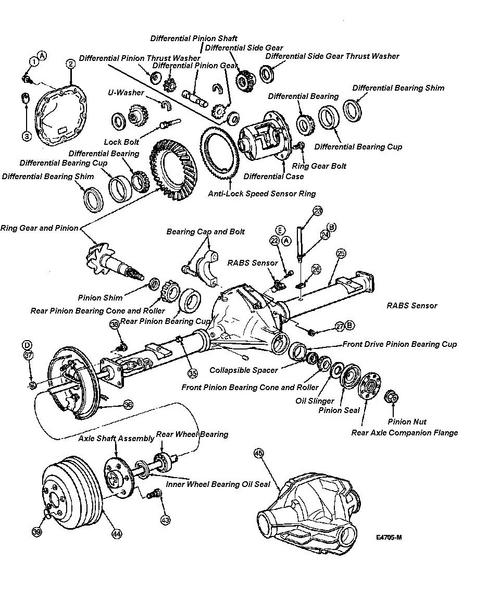

Get you a piece of 1/4" plate about 3 ft long, take your cutting torch and cut it so two or three holes can be drilled in one end to hold the Companion Flange with a notch cut out to turn the Pinion Nut. If you need a photo I will and post one of the tool I made. Bolt the 1/4" plate tool to the Companion Flange where you removed the Drive Shaft (you did mark the drive shaft in relation to the Companion Flange didn't you) from and the other end lying on the ground. Remove the Pinion Nut with a 3/4" drive ratchet. Mark the Companion Flange in relations with the end of the Pinion Shaft. Pull off the Companion Flange with a puller. With a big screwdriver and hammer work the Pinion Seal out. Reach in and take out the Front Pinion Bearing and Collapsible Spacer.

Put in a new Collapsible Spacer to make the new Pinion Nut turn hard. Replace the Front Pinion Bearing. Tap the new Pinion Seal in very carefully with a hammer. Put the Companion Flange back on lining up your marks. Start your new Pinion Nut, Bolt the 1/4" plate tool to the Companion Flange and tighten the nut with a 3/4" drive ratchet until the play is gone, being careful not to over tighten. Now tighten the nut very little at a time (about a 1/16 turn) and keep rechecking the preload with an inch lb. beam type torque wrench (yes I know you have to keep taking the 1/4" plate tool off and on). But keep this up until you get a used bearing torque of 8-14 lb-in.

Never back off the nut, if you get it too tight you will have to start all over with a new Collapsible Spacer, Seal and Nut.

Last edited by subford; 08-27-2005 at 07:07 PM.

#26

I am with subford. Except I would measure the preload before backing the pinion nut off. Then set it back to those numbers.

The 8-14 inch lbs is with the carrier out, you will have it in so just set it back to what it was.

Although technically it would be best to remove the carrier, I have never seen the "put it back to what it was" method fail.

The 8-14 inch lbs is with the carrier out, you will have it in so just set it back to what it was.

Although technically it would be best to remove the carrier, I have never seen the "put it back to what it was" method fail.

#27

what would make fluid come out of the vent tube on the rear axle? I have changed the fluid twice made sure it was filled properly, and I still get the fluid out of the vent tube. I have a F 150 4 x 4 with 3.55 limited slip rear end. People I have talked to say that it is caused by towing or water. Well I do not tow with it and other than rain and snow it is dry.Any suggestions please. Thanks